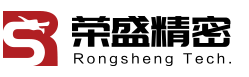

Surface treatment

Various color treatments

Surface treatment is a process that artificially forms a layer on the surface of a base material that has different mechanical, physical and chemical properties from the base material.

The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For metal castings, our more commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, and surface spraying. Surface treatment is to clean, sweep, deburr, remove oil, and remove scale on the surface of the workpiece.

Consultation The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. For metal castings, our more commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, and surface spraying. Surface treatment is to clean, sweep, deburr, remove oil, and remove scale on the surface of the workpiece.